Information

Comprehensive analysis of control cables and their metal shielding design standards and application requirements

Release time: 2024-07-24

First, the conductor and voltage requirements

1, conductor material: control cables should be used for high conductivity copper conductor, to ensure the stability and efficiency of signal transmission.

2, rated voltage: the rated voltage of the cable should not be less than the working voltage of the connected electrical circuit, the recommended choice of 450/750V grade to meet the needs of most industrial and power systems.

Second, insulation and sheath selection

Insulation and sheath type: According to the temperature and humidity of the laying environment, chemical corrosion and mechanical stress and other conditions, a reasonable choice of cable insulation and sheath type, to ensure the long-term stable operation of the cable.

Third, the number of cores configuration principles

1, multi-core cable applications: control and signaling cables are prioritized to use multi-core design to facilitate wiring and management. Core cross-section of 1.5mm² and 2.5mm², the number of cores should not exceed 24; cross-section of 4mm² and 6mm², the number of cores should not exceed 10.

2, spare core: according to the cable length, cross-section and laying conditions, reasonable configuration of spare core to improve the flexibility and scalability of the system.

3, circuit separation: clear distinction between the different nature of the electrical circuit, to avoid AC, DC, strong and weak power circuits share the same cable, in order to reduce mutual interference.

4. Loop pairing: The round-trip wires of weak circuits should be placed in the same cable to ensure the integrity and accuracy of signal transmission.

5, transformer circuit: from the same transformer of the three-phase and neutral conductor should be uniformly placed in a cable, to facilitate management and maintenance.

Fourth, the cross-section selection criteria

1, current loop: to ensure that the current transformer error within the allowable range, select the appropriate cable cross-section.

2, voltage circuit: according to the maximum load voltage drop of the cable does not exceed 3% of the rated secondary voltage to select the cross-section.

3、Control circuit: ensure that the voltage drop between the control power supply and the controlled equipment does not exceed 10% of the rated value, and reasonably determine the cross-section.

4、Strong and weak power circuits: the cross-section of strong power control circuit is not less than 1.5mm², and the cross-section of weak power control circuit is not less than 0.5mm².

5、Measuring circuit: Follow the requirements of "Design specification for electric measuring instrumentation device of electric power installations" GB/T 50063.

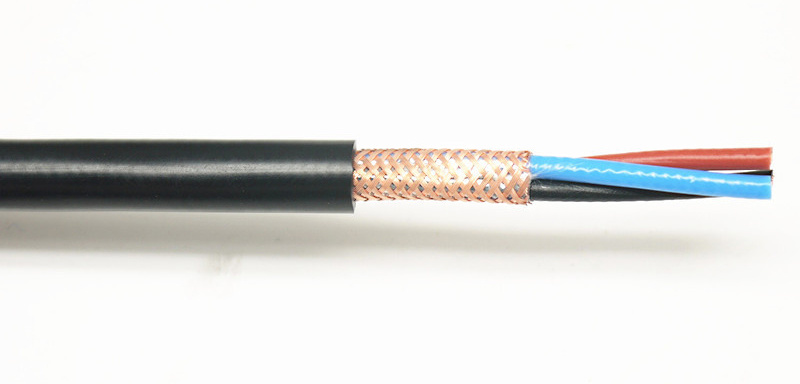

V. Metal shielding requirements

1, strong circuit: non-high-pressure environment or high-voltage cable adjacent to the case, you can omit the metal shielding, but specific interference occasions need to consider adding.

2, weak power and protection circuit: vulnerable to interference with weak telecommunications signals, control circuits and microcomputer-based protection system, must use metal shielding cable.

3, shielding type selection: according to the type of electrical interference (such as electromagnetic induction, electrostatic induction) and system requirements, the choice of total shielding, double-layer total shielding, stranded core sub-shielding and other suitable shielding type.

4, grounding:

① computer monitoring system analog signal circuit using a centralized one-point grounding.

② integrated circuits, microcomputer protection circuits in the switchyard and the control room at the same time grounding, and other cases according to the type of interference to choose a point or two points of grounding.

③ Double or composite shielding should be grounded separately to ensure the grounding effect and to prevent transient current burned shielding layer.

④ It is strictly prohibited to use the spare core wire to replace the shield grounding.

Sixth, the summary

Control cable and its metal shielding design and selection need to take into account the electrical performance, environmental adaptability and system safety and other factors to ensure that the cable in a complex electrical environment, stable operation, to protect the reliability and safety of the entire system.

Translated with www.DeepL.com/Translator (free version)

oversea@hichain.com.cn

oversea@hichain.com.cn

+8617328576881

+8617328576881