WHICH SOLUTIONS

WHAT PROBLEMS CAN WE SOLVE?

OUR PRODUCTS

PRODUCTS APPLICATION

LED industry

automation machinery and equipment

energy storage

new energy

Elevator industry

Commercial air conditioning

High-End Equipment

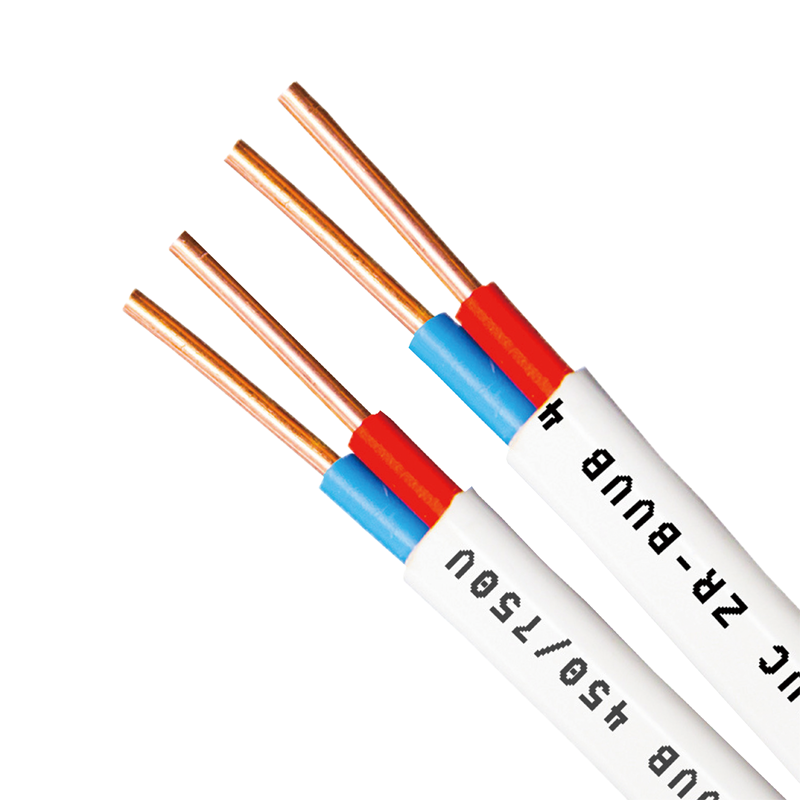

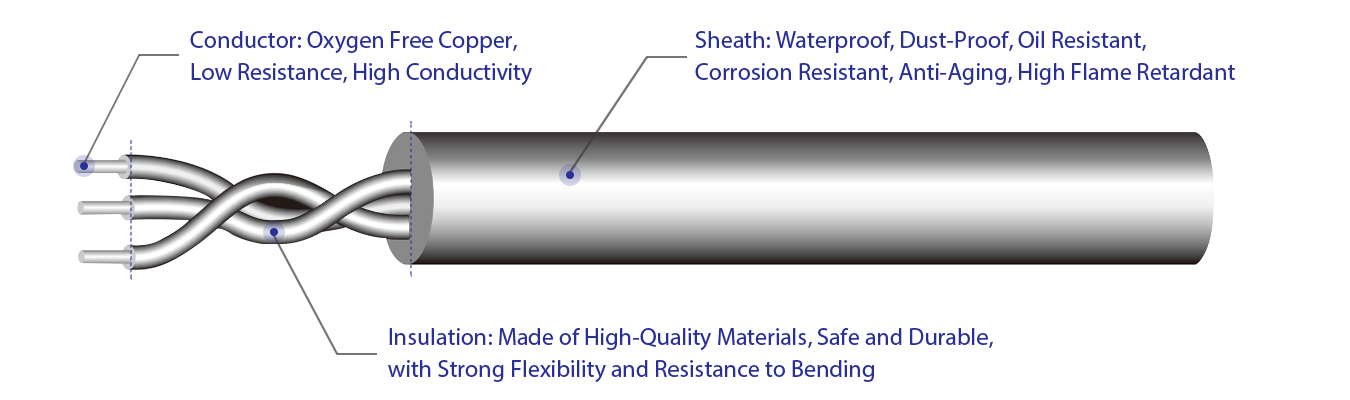

It is widely used in home and environmental lighting, with insulation and flame retardant, high temperature resistance, safety and reliability, light weight, wear resistance and other characteristics.

Read More

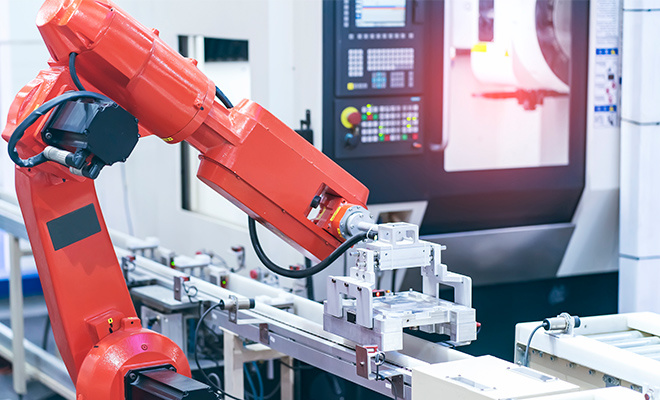

automation machinery and equipment

These cables are used in robot torsion-resistant bodies, drag chain wiring, high-end CNC machine tools, and automated equipment.

Read More

Energy storage cable refers to the cable used in the energy storage system, which can be used to connect the energy storage device and connect it with the rest of the system. Strong carrying capacity, strong resistance, good stability, high safety performance.

Read More

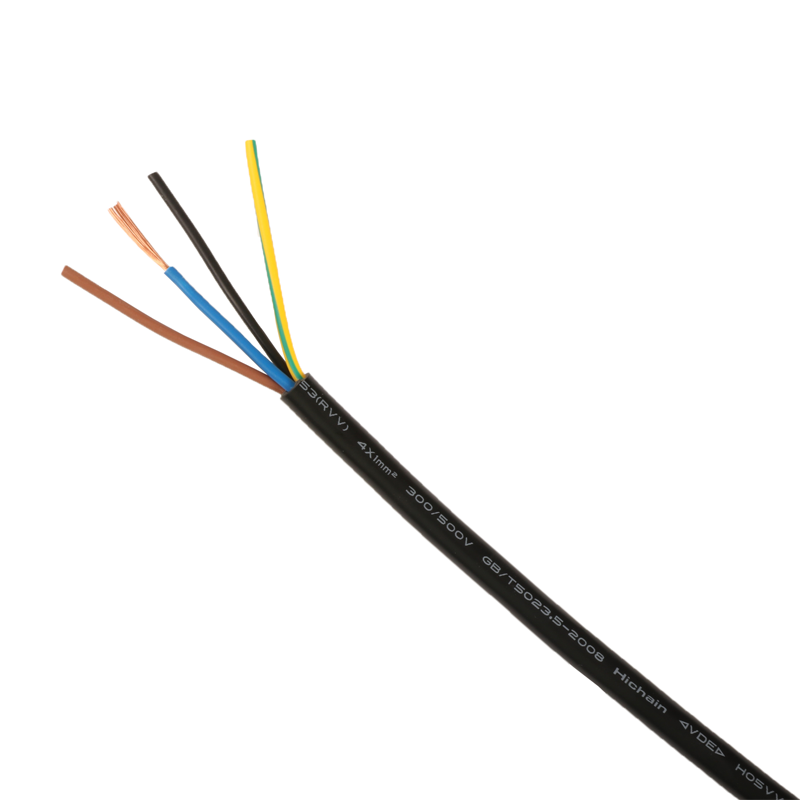

These cables are primarily used in clean energy generation systems such as solar power, wind power, energy storage, as well as other applications requiring high-quality power transmis- sion, such as medical equipment, computer data centers, and new energy vehicles.

Read More

These cables are used in the power, signal, and control integrated wiring systems of escalators, including mainframe power, maintenance areas, up and down platform control boxes, emergency stop switches, and travel switches.

Read More

These cables are mainly used in electronic equipment such as cell phones, audio systems, televisions and computers, as well as wires and power cords conforming to the national standard for electronic cables (Vl.758).

Read More

These cables are used in various machinery, industrial equipment, intelligent robots, battery semiconductor manufacturing equipment, and other fields.

Read More

Talk to us. We're on your side!

We welcome all projects, regardless of size

WHO WE ARE

WHY CHOOSE HICHAIN?

Our product line covers wires and cables, copper conductors, various environmentally friendly cable adhesives, sheet metal cabinets, electrical control equipment, etc. We are committed to providing comprehensive solutions for low-voltage and weak current wires, cables, and wiring harnesses for customers in various industries.

Read More

oversea@hichain.com.cn

oversea@hichain.com.cn

+8617328576881

+8617328576881